金属加工冲压件表面细微瑕疵分类与定位

3C、电子、机械产品中的金属工件生产:金属冲压工艺

冲压是成型加工方法之一,靠压力机具、模具对金属板材、管材等施加应力,使之产生变形或分离以取得所需形状及尺寸的工件。冲压成型过程中,材料表面不受破坏,故有较佳的表面品质,适合表面喷漆、电镀等其他处理。然而由于加工环境及其他随机因素,冲压件表面仍会出现细微瑕疵,如R角毛边、脏污、水渍、压痕、刮痕及M-mark等,需即时检出以利后续工序施作。

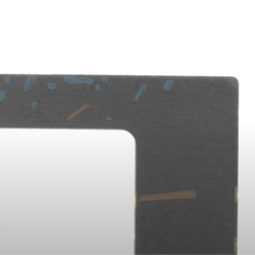

金属冲压件加工瑕疵:不易察觉的毛边、细痕、油渍、水渍

金属冲压件上可能出现的瑕疵种类繁多且形态不一,油污及水渍更是不易观察。另一方面,工件在取像时的亮度也各有差异,造成瑕疵检测的执行相当不易。

金属加工品的品管助手:AI瑕疵检测

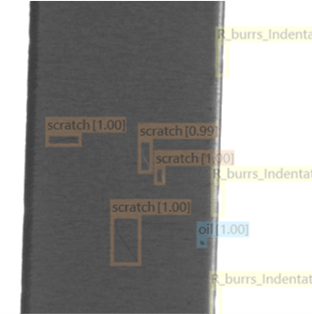

使用所罗门 SolVision AI影像平台的实例切割技术,以不同亮度的各式瑕疵影像作训练,经训练的AI模型可轻易检出各式冲压件上的瑕疵,例如:浅刮痕、油污、水渍、毛边大幅提升产品的表面品质。

金属加工冲压件瑕疵检测案例

瑕疵分类

Blue 油污, 水渍

Green 白色缺陷

Orange 刮伤

Yellow R角毛边及压痕

原图

检测结果

检测结果

检测结果