AccuPick LM

AccuPick LM Product Description

AccuPick LM is an efficient automated material handling and positioning solution developed by Solomon. Through the innovative use of markers, AccuPick LM quickly detects changes in item position and orientation using a camera mounted on the robot arm. These markers serve as reference points, enabling the robot to adjust its movements and compensate for any deviations. This transforms the coordinate system from being centered on the arm to focusing on the marker itself, ensuring more dynamic handling and positioning.

In automated production line applications, precise material handling and positioning are essential. AccuPick LM simplifies these processes, eliminating the need for additional hardware or complex positioning fixtures.

AccuPick LM Features

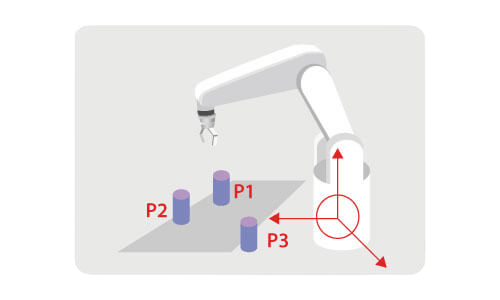

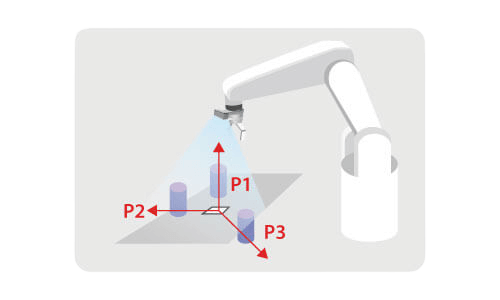

Displacement Recognition

The camera mounted on the robot arm swiftly scans the marker to update coordinate information, accurately determining the relative position even when the target object or arm position changes.

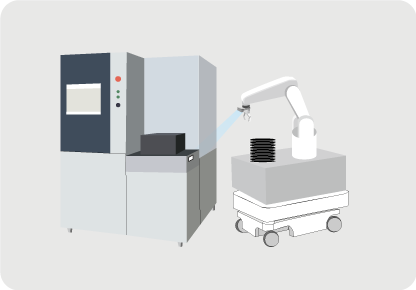

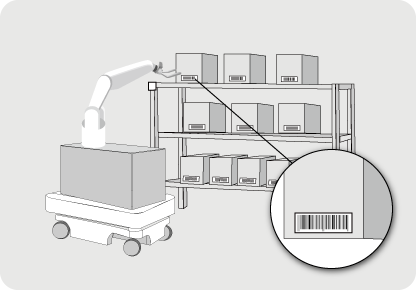

AGV/AMR Integration

Perfect for dynamic work environments, allowing your robotic arm to collaborate with AGV/AMR or mobile stacking, accurately identifying object positions even in dynamic workspaces.

Robot Compatibility and User-Friendly Operation

AccuPick LM effortlessly integrates with various robot models, providing users with a seamless and user-friendly experience for both setup and operation.

Plug-and-Play Rapid Deployment

AccuPick LM is a bundled system designed for easy and rapid deployment, eliminating the need for extensive programming or specialized expertise to operate.

Barcode Scanning Capability

AccuPick LM goes beyond fast and precise positioning, providing a built-in barcode scanning feature capable of recognizing barcodes within the field of view (FOV), enhancing efficiency and accuracy in object identification.

Future-Proof Scalability

Solomon offers a range of industrial automation solutions, encompassing AI detection and 3D vision systems. AccuPick LM enables the seamless integration of the latest AI and 3D vision innovations into existing production lines, facilitating a complete embrace of Industry 4.0.

AccuPick LM Applications

Material Handling

[Cobot Mounted on an AGV/AMR]

AccuPick LM swiftly and accurately completes material handling tasks by scanning the marker, moving to the workstation, and performing the desired action. Its precise handling capabilities remain unaffected even if the AGV/AMR is not perfectly aligned.

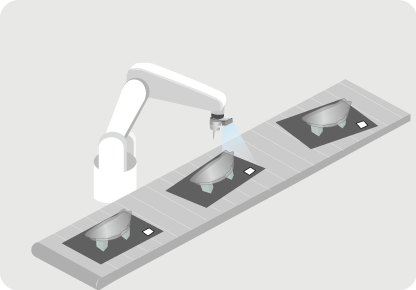

Material Dispensing

[Cobot Affixed on a Workbench]

In automated production lines, when performing tasks such as material handling, painting, or various dispensing applications, even if the tray arrives at varying angles or with deviations each time, the robot can find the relative position of the target object by using its vision to locate the marker.

Barcode Scanning

AccuPick LM’s barcode scanning function ensures accurate identification of object locations, effectively streamlining workflow processes.

Leading Multinational Customers

Our in-house developed AI and 3D machine vision systems have positioned Solomon as a global leader in industrial automation technology solutions. Our international clientele includes companies and enterprises across diverse industries including semiconductors, electronics, automotive, food, textiles, logistics, and more.