META-aiviCase Study

Electrical Wiring Inspection Using AR + AI

Customer

The customer is a manufacturer operating a smart factory.

Case

Ensuring Electrical Safety Through Circuit Configuration Inspection

As manufacturing becomes increasingly automated through the integration and connectivity of machinery and systems, factories are achieving greater operational efficiency. However, ensuring the correct wiring configuration for each machine is crucial to maintain safe and efficient operations. The wiring setup can vary from one machine to another so it’s important to prioritize wiring inspection and control to achieve the benefits of automation without risking downtime or compromising safety.

Challenge

Standardization of Equipment Wiring and Inspection Systems

Personnel must verify wiring to ensure the correct and safe operation of equipment. Without a robust verification mechanism, accidents such as electrical fires can occur, posing a risk to personnel and damaging the equipment and facility. Additionally, inadequate training or a lack of understanding of complex wiring may result in personnel being unable to effectively communicate encountered issues during inspection, further increasing the risk of errors and equipment failure.

Solution

META-aivi Helps Personnel Perform Complex Wiring Inspections

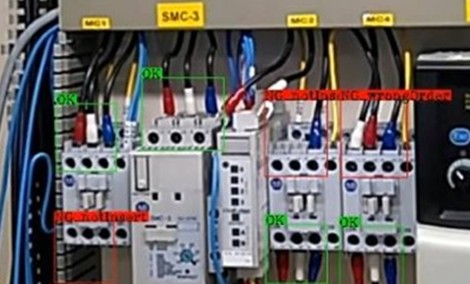

During the wiring inspection process, META-aivi can recognize multiple types of circuit images and verify wiring configuration during inspections. META-aivi displays the standard operating procedures on the device screen, guiding the operator to correct any errors while also outputting detection results with a timestamp. This creates a digitized inspection record that can be remotely viewed by back-end personnel and uploaded to the facility’s cloud database for compliance and archiving.

META-aivi Inspection Results

Using AI technology META-aivi inspects the wiring panel and identifies mismatched cables