SolMotionCase Study

Automated Rail Edge Trimming Using AI

Customer

The customer is ICS SAKABE, a Japanese systems integrator working on a project for Kyushu Railway Machinery Manufacturing Co., Ltd., which specializes in manufacturing turnouts, rail processing, and rail welding work.

Case

Sustaining Railway Joint Plate Supply

The end user, Kyushu Railway Machinery Manufacturing Co., Ltd., serves as the foremost producer of joint plates for railway tracks in Japan, playing an essential role in maintaining stable operations nationwide. Given the critical importance of railways in transportation infrastructure, ensuring a steady supply of joint plates is paramount. Emergencies such as disasters or accidents may require round-the-clock production to meet heightened demand, emphasizing the necessity for a stable supply chain while also minimizing worker strain and risks.

Challenge

Automating Rail Edge Trimming

Rail joint plates required manual edge trimming before undergoing the heat treatment process, with nearly 1,000 trimmings completed daily. Despite its apparent simplicity, this task presented inherent risks. The company sought the integration of robotics and Internet of Things (IoT) technology into the post-heat treatment transportation and delivery process of rail joint plates to enhance efficiency.

Solution

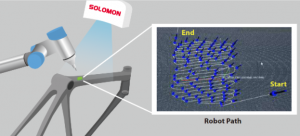

Automation with Vision Guided Robotics

The customer implemented SolMotion vision guided robotics to automate this crucial task. SolMotion’s advanced AI 3D machine vision technology ensures precise positioning of joint plates, facilitating seamless edge trimming. Integrated by ICS SAKABE, the vision guided robotic system enables unmanned operations, significantly bolstering product supply stability, reducing worker risks, and enhancing overall efficiency.