SolVisionCase Study

PCB Assembly Inspection Using AI

Case

Component Verification in PCB Assembly

The production of assembled printed circuit boards (PCBs) involves intricate manufacturing processes for various electronic components like resistors, transformers, and chipsets. To optimize production throughput, it’s crucial to establish checkpoints for verifying the presence and accurate placement of each component.

Challenge

Limitations of Manual Inspection in PCB Assembly

Manual visual inspections are error-prone due to the complexity of assembled PCBs, which can feature numerous parts and configurations. Subtle differences may go unnoticed by the human eye, leading to missed or inaccurate detections. Additionally, optimizing manual inspections is challenging due to their inherent limitations.

Solution

Enhancing PCB Inspection Efficiency with SolVision

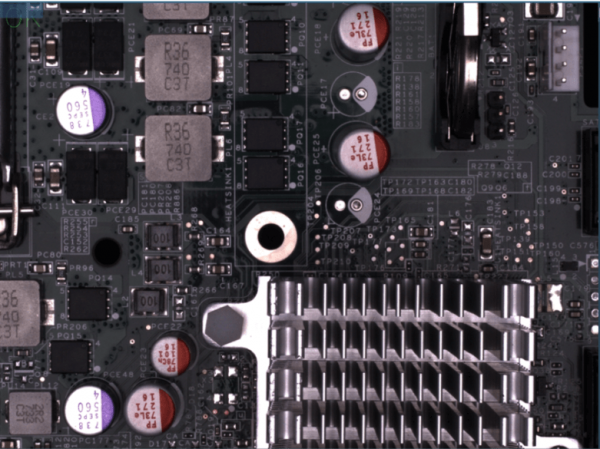

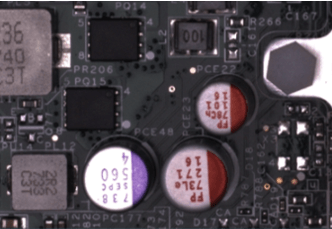

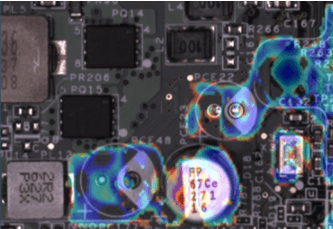

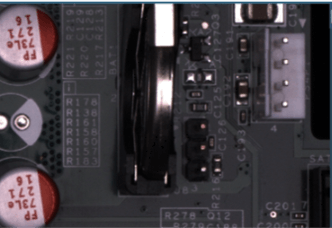

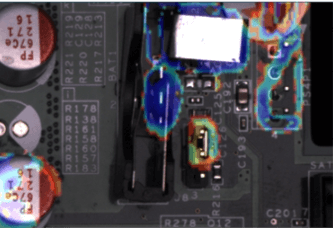

SolVision‘s anomaly detection AI tool leverages one-shot learning to train an AI model from a designated golden sample. This enables efficient recognition of defects and anomalies such as incorrect part placement or missing components on assembled PCBs. Through rapid image analysis, the AI vision system precisely discerns differences between the golden sample and the product, substantially enhancing inspection efficiency.

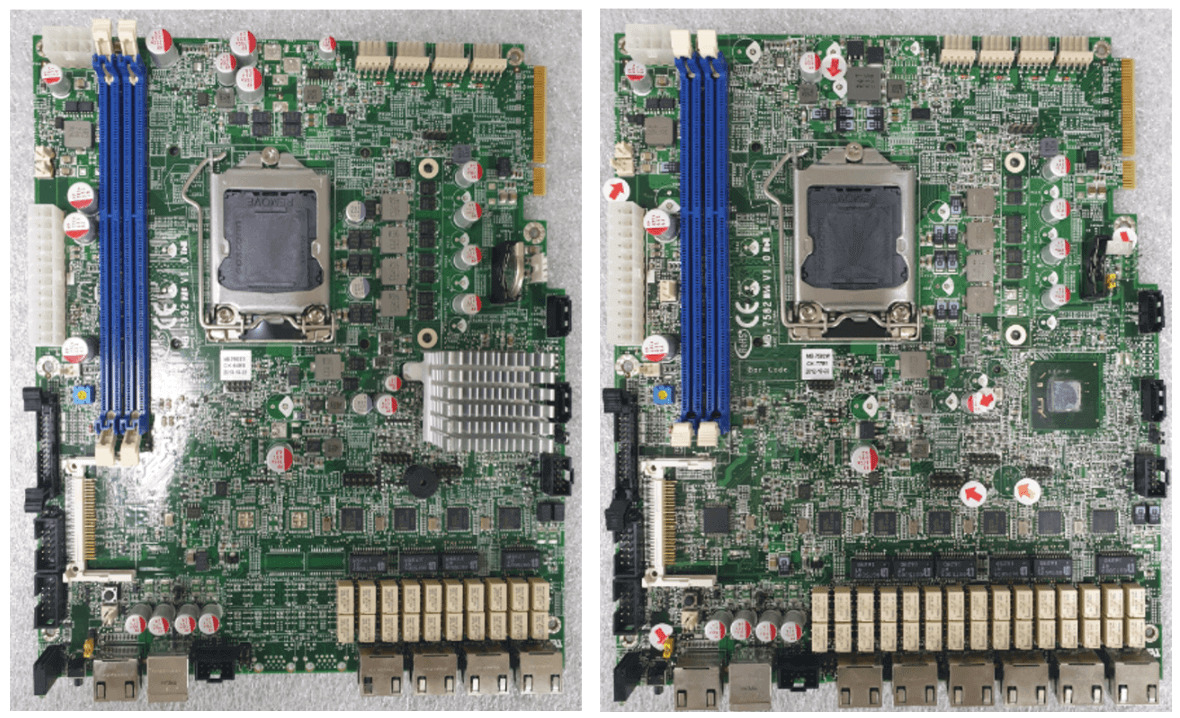

Defect Detection

Golden Sample

Defective PCB

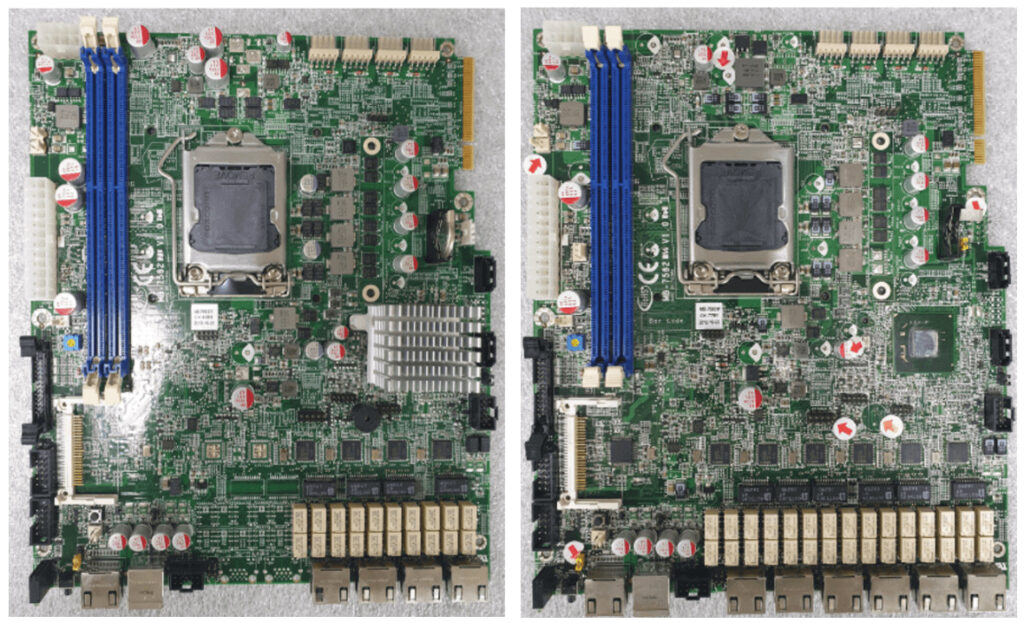

Golden Sample

Capacitor Defect

Golden Sample

Missing Components