SolVisionCase Study

Quality Inspection of Golf Clubs

Detecting defects on casted and forged products

Golf club heads: the secret to a successful swing

A golf club usually comprises a club head, shaft, and the grip. The club head is the main contact surface between the club and ball, and can make or break a swing. Materials used for the club head are usually soft and strong, such as titanium.

Trademarks and tricky design patterns

The club head makes up the most important part of golf club assembly, and consumers attach great importance to the finesse of the finishing. Usually made of cast and forged composite materials, club heads are susceptible to minor defects on the surface that need to be detected and rectified before leaving the factory. However, a club head often has a brand logo, design features, and metallic luster, all which make automated defect detection hard to implement.

Inspecting metal surfaces using artificial intelligence

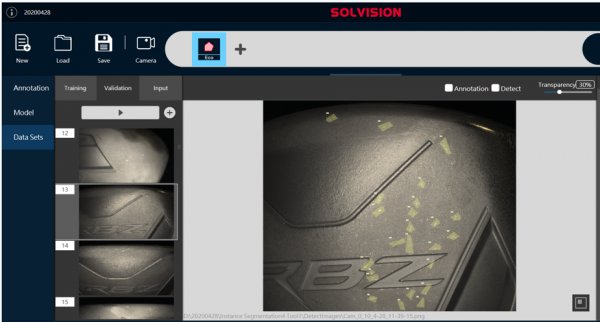

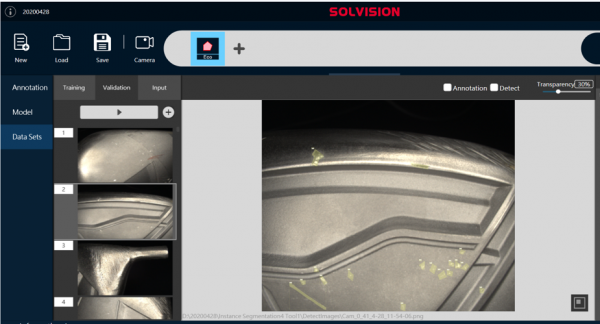

With AI-based SolVision, production imperfections on club heads can be detected no matter their size, appearance, or location. The system trains an AI model using sample images of defective products, so it can recognize different defects based on their unique characteristics, and mark them on images scanned during the inspection process.

AI Inspection

Defective Surface 1

Defective Surface 2