SolVisionCase Study

Laser Welding Defect Detection Using AI

Case

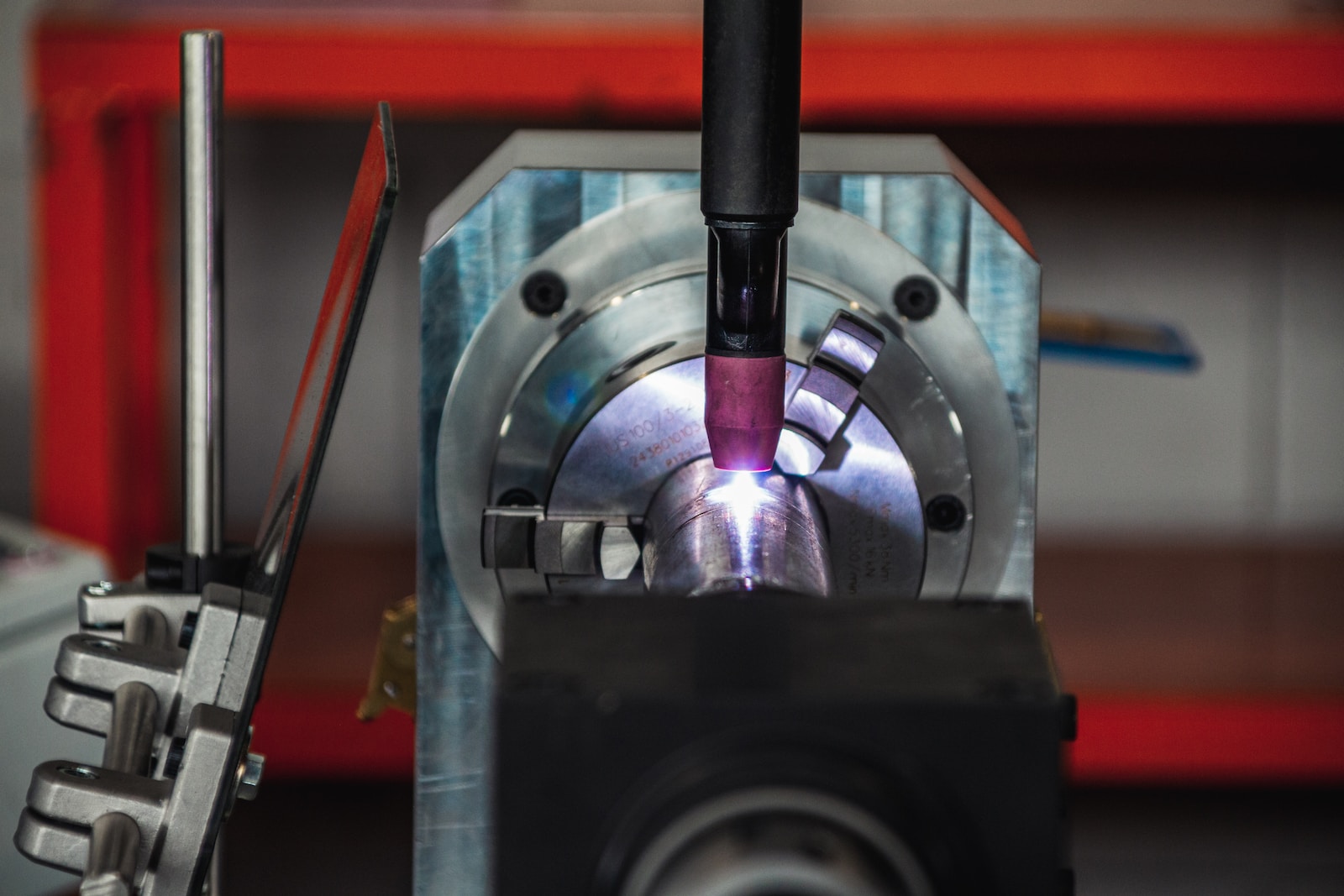

Precision Laser Welding

Among the different types of welding, laser welding stands out for its use of a focused light beam to quickly melt, vaporize, cool, and solidify materials, creating strong joints. It is easy to set up and provides fast, precise welding, even for heat-resistant materials. This technique offers superior efficiency and quality compared to traditional welding methods.

Challenge

Ensuring Consistent Welding Inspection

Laser welding encompasses two primary methods: heat conduction welding and keyhole welding (also known as deep penetration welding), each yielding unique weld characteristics. However, the constantly changing welding positions and patterns present a formidable challenge for rule-based inspection systems to accurately identify weaving patterns or detect missed welding spots and other production errors. As a result, manual welding defect inspections are typically employed, contributing to inconsistencies in welding quality.

Solution

AI-Powered Welding Quality Control

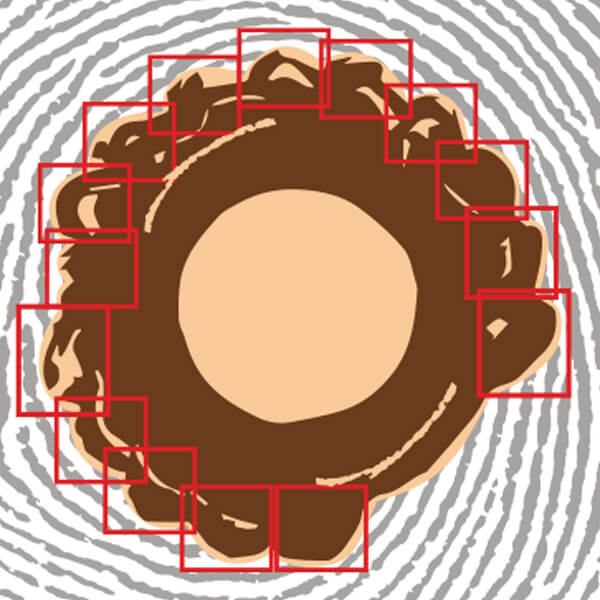

SolVision is an AI-based visual inspection system that enhances welding quality control. Using a golden sample image to train an AI model, SolVision swiftly and accurately detects welding inconsistencies, surpassing conventional inspection methods in precision and efficiency. This intelligent system precisely identifies welding defects and pinpoints missed welds using classification and segmentation AI tools. Through advanced deep learning techniques, SolVision can also analyze welding weave patterns, further optimizing the inspection process.

Defect Detection

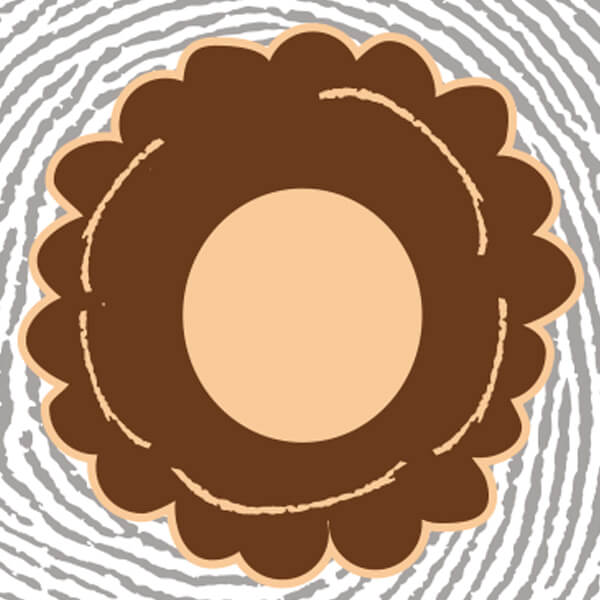

Golden Sample

Anomalies Detected