SolVisionCase Study

IC Tray Inspection Using AI

Case

Ensuring Quality in IC Tray Handling

After chips undergo inspection and singulation processes, they are transferred into designated compartments within IC trays. These trays securely hold the chips until they are ready for final shipment to customers. However, the small size and light weight of the chips make them prone to duplication, misplacement, tilting, or inversion during handling within the trays.

Challenge

Addressing Unpredictable Placement Scenarios

The issue of missing or misplaced semiconductor chips presents a wide array of challenges, resulting in numerous variations in their placement—varying in location, angle, and orientation. Traditional rule-based systems struggle to effectively identify and categorize all types of defective placements due to the sheer complexity and variability involved.

Solution

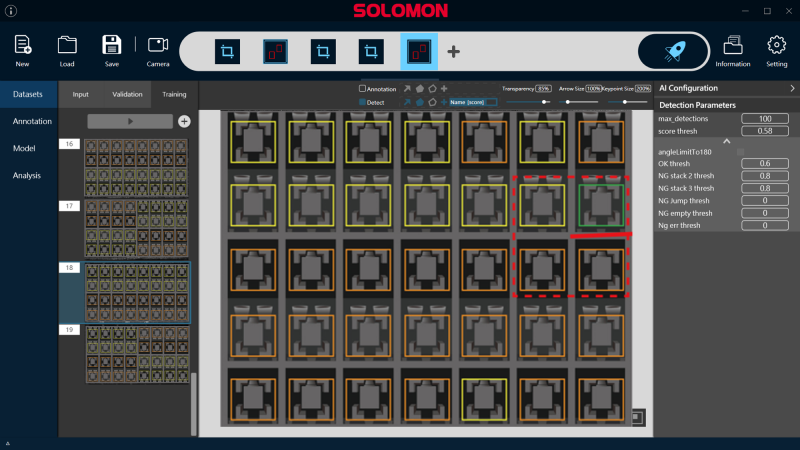

Utilizing AI for IC Tray Inspection

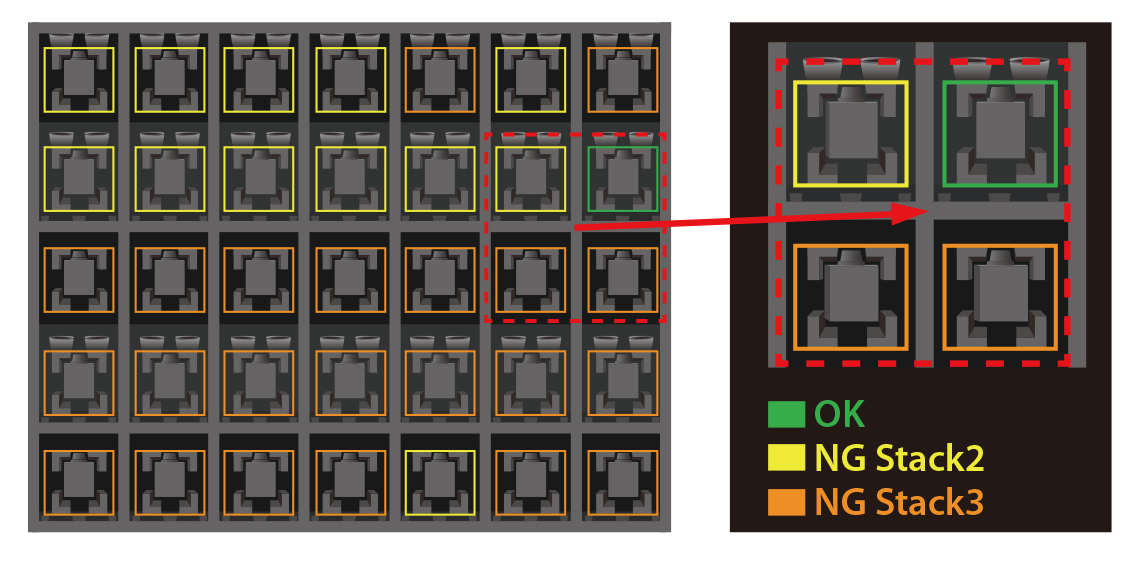

SolVision‘s segmentation tool employs AI image processing to analyze the diverse placement scenarios of chips on IC trays. Through rapid training, the AI model accurately identifies and highlights deviations in chip placement, enabling precise recognition and localization of abnormally placed chips with exceptional efficiency.

AI Inspection

OK = Correct Placement

NG Stack2 = Incorrect Placement (2 overlapping ICs)

NG Stack3 = Incorrect Placement (3 overlapping ICs)