AccuPickCase Study

Small Parts Bin Picking

Customer

The customer is a widely recognized aerospace parts manufacturer based in Europe, operating globally.

Challenge

Handling Diverse and Numerous Parts for Automated Kitting Line

The customer needed a solution to establish a completely automated kitting line for their operations. The main challenge was handling a large volume of parts, which varied in size and had irregular SKUs. Some parts were as small as 5 mm.

This resulted in a significant daily labor effort to organize them using a flex feeder, which lacked the necessary versatility. Therefore, the customer opted to search for a more advanced and agile solution.

Solution

Achieving Automation Efficiency with Solomon’s Bin Picking Solution

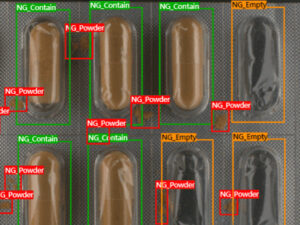

AccuPick, Solomon’s smart bin picking solution, provided the customer with a fully comprehensive vision system capable of identifying over 50 different parts within a workstation.

Leveraging the power of Solomon’s AI software, AccuPick successfully recognized 5 mm washers, even when other objects were overlapping.

Traditionally, detecting objects of such small size has posed challenges for regular 3D vision solutions. However, AccuPick overcame this obstacle.