SolMotionCase Study

Grinding Metal Parts with Vision Guided Robotics

Automating Grinding Processes for Molded Products

Case

Grinding Molded Metal Parts

Grinding, despite being a commonplace process in metal component manufacturing, remains one of the most intricate tasks. Achieving the desired finished product is no easy feat, as it demands strict adherence to quality, repeatability, and reproducibility standards. This becomes all the more challenging due to the scarcity of skilled technicians and the inherent inconsistency in manually-applied pressure.

Challenge

Automated Grinding Without Vision

Automating grinding without vision becomes a near-impossible task due to the demanding precision needed. For instance, when manufacturing a metal bicycle frame through injection molding, the semi-finished product frequently exhibits uneven lines from the mold case. To meet production standards, an additional grinding process is necessary. However, the flaws are irregularly shaped and scattered across various points on the metal frame, making manual grinding an arduous and delicate process. This often leads to product anomalies or breakage.

Solution

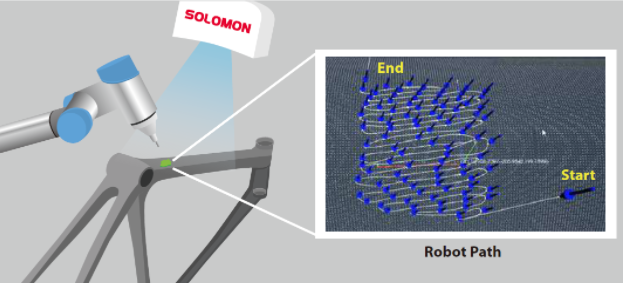

SolMotion 3D Matching for Precision Grinding

SolMotion‘s cutting-edge 3D matching technology offers a powerful solution for comparing an object’s profile with a golden sample or CAD model. By generating 3D point clouds, it reveals an error map pinpointing production deviations on the object. Leveraging this information, the system derives a precise 3D path for the robot, guiding it with a grinding tool. As a result, this innovative process significantly reduces rework and waste caused by substandard products, leading to cost savings over time. This reliable and efficient approach ensures high-quality output and enhances overall productivity.