SolVisionCase Study

Inspecting Safety Certification Marks

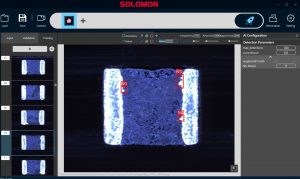

AI automated detection of defective certification marks

Reliability of certified products

Safety certification marks are used to encourage products to comply with safety, health, and environmental regulations or standards. Consumer and household electronics usually have these labels which are also further differentiated into domestic and international certification. A guarantee of reliability, these certification marks prove that relevant tests have been conducted to ensure product safety.

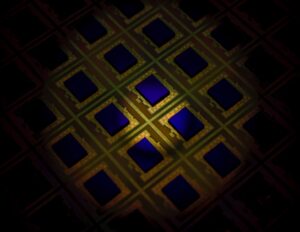

Detecting missing safety certification marks

Safety certification marks have many different test standards for example CE, EAC, that are represented by individual icons. Manufacturers will also indicate product serial numbers, manufacturing location, power requirements and usage methods alongside the certification marks. The extensive amount of information in this area makes it prone to printing errors that are hard to detect, which affects product sales and use of goods.

AI anomaly detection for printed matter

Enabled by artificial intelligence, SolVision offers a visual inspection solution that can be trained using just a few images of golden samples in unsupervised learning mode. The developed AI model is capable of conducting comparisons with golden samples to automatically recognize and label differences on the scanned images, in order to identify defective printing.