SolVisionCase Study

Product Label Inspection Using AI

Case

Ensuring Precision in Product Label Inspection

Accurate product label inspection is essential in electronics manufacturing, where precise serial number compilation directly affects product development, production efficiency, and inventory management. Errors in label screening can disrupt these processes, leading to decreased operational efficiency and significant resource wastage. This case study highlights the critical role of meticulous label inspection in ensuring seamless and efficient manufacturing operations.

Challenge

Difficulties in Label Inspection

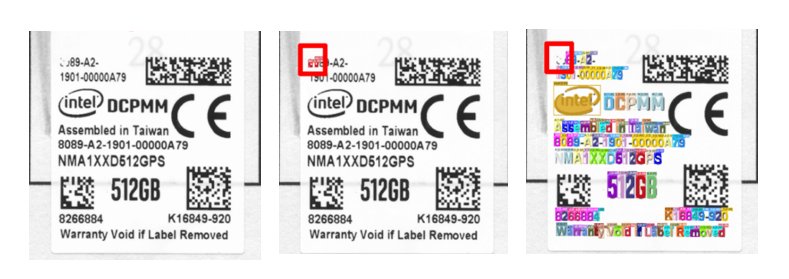

Inspecting printed labels presents several difficulties. Minor aesthetic defects in the text or numbers are common and can be challenging for conventional vision systems to detect. These imperfections can lead to inaccurate recording of product numbers, resulting in disorganized inventory management and disrupted production processes.

Solution

AI-Powered OCR for Superior Label Inspection

SolVision offers a highly efficient OCR solution utilizing AI deep learning. The segmentation tool within SolVision can identify various types of text and number defects on labels, even those that are irregular or subtle. When fonts are too damaged to be recognized, the system employs defect detection to accurately identify them. This enhances material management and significantly improves the accuracy of inventory management.

AI Inspection

Product Label Defect Detection

Product Label Optical Character Recognition