AccuPickCase Study

Metal Parts Bin Picking

Customer

The customer is Motion Technique, an India-based systems integrator working on a project for Siemens at their switchgear factory in India.

Challenge

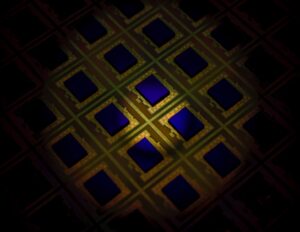

Complex Laminated Steel Components Recognition and Handling

A vision system was tasked with accurately recognizing the orientation and position of laminated steel components—including rotation, yaw, and tilt—and guiding the robot to pick up and place the components at a specific location on a feeding conveyor.

Due to the depth of the bin (740 x 365 x 230 mm) and the small size of the components, a longer gripping tool was employed to minimize the risk of collisions with the bin.

Moreover, the complex shape of the items, limited picking angles, and their random arrangement posed challenges for CAD-based localization technology, preventing it from achieving the desired outcome for the contractor.

Solution

AI-based Localization and Motion Planning for Efficient Component Handling

Solomon’s AccuPick AI-based localization technology and SolScan 2.3 MP scanner enabled Motion Technique to accurately identify the potential orientation of each component. These findings were then utilized to position the components within a custom-designed slider.

The implementation of AccuPick’s ROS Motion Planning ensured that the robot could execute its picking tasks without any collisions with the bin. Remarkably, all of Siemens’ requirements, including scanning, recognition, motion planning, and the physical picking and dropping of the components with a Universal Robots UR10 robot, were successfully accomplished within a timeframe of 6 seconds.