SolVisionCase Study

Glass Bottle Inspection Using AI

Detecting defects on layered glass bottles with AI

Translucent glass bottles

Gradient colored glass is made by using high-pressure air jets to create mist particles on the glass surface. Also referred to as matte glass, there are two popular production methods: internal sandblasting and external sandblasting. The gradation style allows for many design styles, while the translucent effect adds to the aesthetics.

Defining defects on gradient colored glass

Sandblasting creates uneven spots and imperfections that vary in color, size and location. As there is no clear definition of defects or their features, logic-based rules cannot be established to implement conventional inspection methods

Smarter inspections with AI

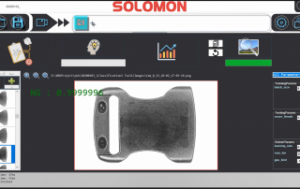

Through advanced image processing, SolVision can fully automate inspection processes to detect production flaws. The system’s Segmentation tool allows the features of defective glass bottles to be learned through sample images. During production, the trained AI model can quickly detect and label the location, angle, and size distribution of different defects on a scanned image.

AI Inspection

Scanned Image

Detection Result