SolVisionCase Study

AI Inspection of Plastic Buckles

Detecting defects on injection molded plastics

Quality of injection molded plastics

Plastic buckles come in many forms and are mostly manufactured in large quantities by injection molding. Many variables can affect the outcome of plastic injection molding processes, including raw materials, molds, temperature, pressure, and production speed.

Surface defects and traditional inspection systems

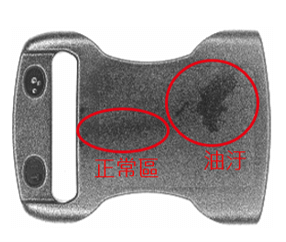

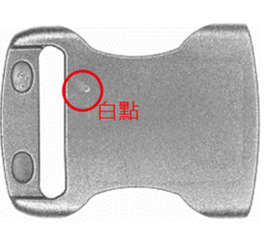

Production flaws commonly seen on plastic buckles range from oil stains and white spots, to burrs and debris. Amongst them oil stains are the most difficult to be detected manually or by rule-based systems, as they are generally less noticeable.

Multi-tool AI defect detection

Powered by artificial intelligence, SolVision features four individual tools designed for different inspection tasks. To identify multiple defects at the same time, the system’s Segmentation and Classification tools utilize deep learning technology to perform recognition of faulty products, and train an AI model capable of detecting defects accurately, including oil stains, in real time.

AI Inspection

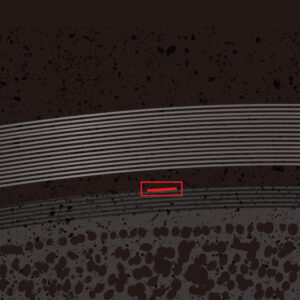

Oil Stain

White Stain

Burrs

Burrs