SolVisionCase Study

Digitizing Machine Dashboards

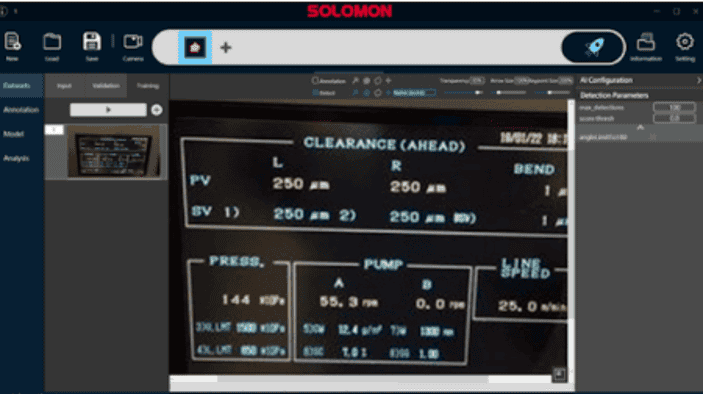

AI-powered OCR of dashboard readings

Gas levels in Optoelectronics

In optoelectronics, manufacturing polarizers require evenly distributed film layers which is achieved by having consistent gas levels. Monitoring compression parameters during gas production is key to improving yield.

Limitations of traditional machinery

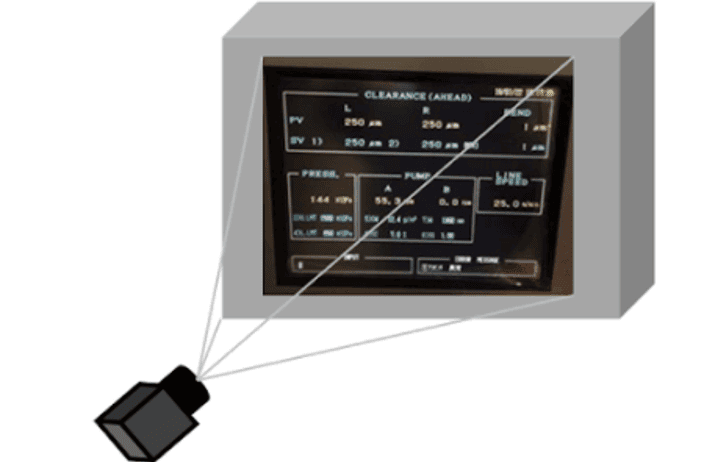

Traditional gas monitoring machines and equipment feature dashboards that display readings but these often lack a digital interface and prevent data from being uploaded quickly to a digital monitoring system, slowing down the manufacturing process.

Digitization with OCR

1. Industrial camera shoots 2D images

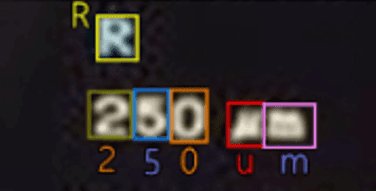

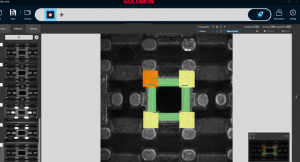

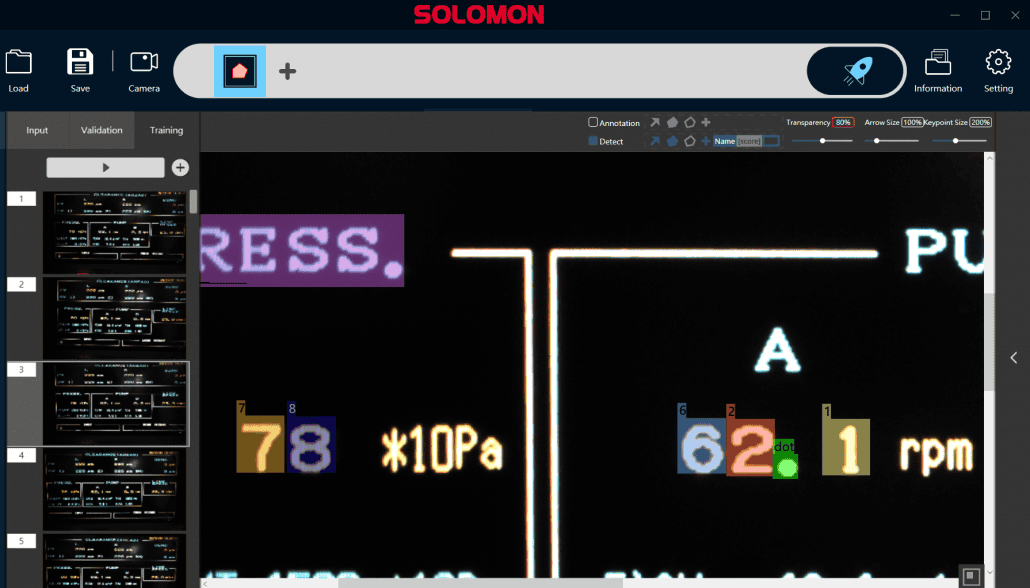

2. Optical character recognition obtains numericals and coordinates

3. Digital information output