SolVisionCase Study

Product Packaging Sequence Detection Using AI

Case

Efficiency and Precision in Coffee Capsule Packaging

Coffee capsule machines have gained popularity in recent years. These machines offer a range of coffee beans in disposable capsules, distinguished by color to signify their origin, flavor, and coffee type. Each capsule is typically assigned a specific position in the segmented packaging box, with proper placement serving as an indicator of both product aesthetics and production quality.

Challenge

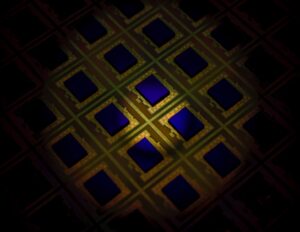

Overcoming Color Recognition Issues in Metal Packaging

Due to the abundant diversity of coffee capsules, a significant number share similar colors that can be challenging for the human eye to discern. These capsules are typically enclosed in metal-based packaging, leading to issues with light reflection during image recognition. Conventional rule-based vision systems necessitate specific lighting sources, lenses, and sensors to identify the subtle color distinctions of coffee capsules. However, these traditional inspection methods prove inefficient when confronted with reflective materials.

Solution

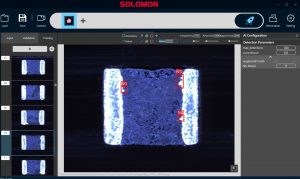

Precision AI Inspection with SolVision

SolVision enhances the automated inspection of coffee capsule placement in boxes. This system empowers artificial intelligence to grasp both the accurate and irregular sequences of capsule placement. By learning from diverse images of various coffee capsules, the AI can swiftly identify and flag incorrectly positioned capsules in a single detection. Moreover, AI image recognition provides advanced capabilities, overcoming challenges posed by highly reflective coffee capsules and subtle color differences, thereby ensuring high detection accuracy.

Presence/Absence

Missing Capsule

Incorrect Sequence