SolVisionCase Study

AI Visual Inspection of Glass Bottles

Detecting Defects on Reusable Wine Bottles

Eco-friendly, Reusable Bottles

In an effort to be more environmentally sustainable, some wine producers have implemented measures to recycle their wine bottles. After cleaning and sterilizing, the bottles are checked for damage or residue before being used again.

Challenge of Detecting Stains and Mildew

Even after the disinfection process, mildew and stains can sometimes remain on the bottle. It is better to detect this beforehand so that any defective bottles can be removed during cleaning. However, checking for defects involves rotating and moving the bottle, and there may be a product label in the way, which makes this process unfavorable for manual inspection and traditional vision systems.

AI Detection Ensures a Safer and More Efficient Cleaning Process

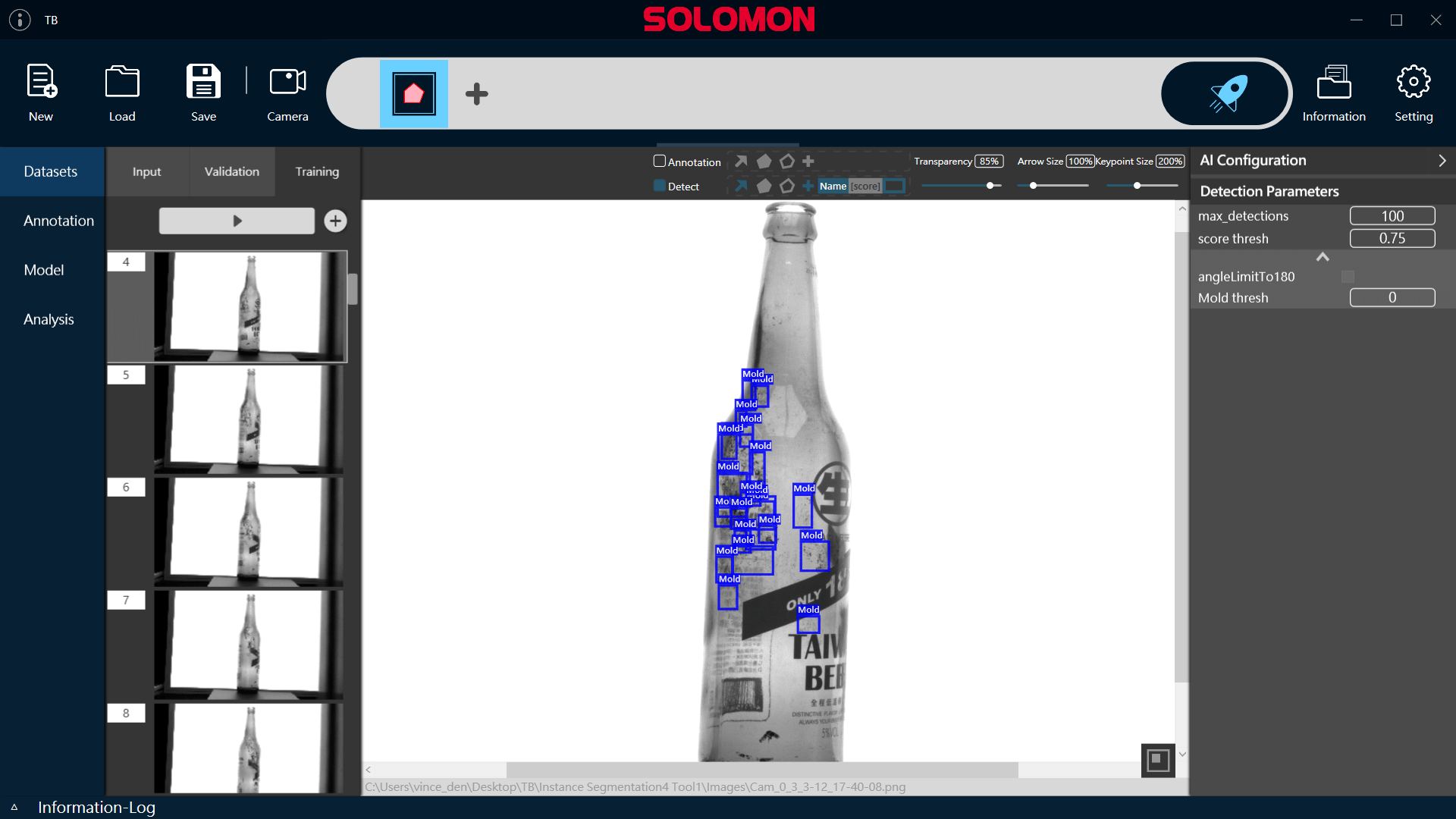

With just a small set of sample images, SolVision can be trained to recognize different types of stains and mildew. The software’s segmentation tool learns the location, color, and features of defects to identify them automatically in real time on the cleaning production line. Inspecting glass bottles thoroughly to accurately locate spots that need to be disinfected ensures the recycling process is safer and more efficient.

AI Inspection Process

Mold plaque distribution

Test results