SolVisionCase Study

Automated Recognition of License Plates & Cargo Container Numbers

Flexible optical character recognition (OCR) with AI

Shipping management and transportation

Cargo terminals provide services such as container storage, maintenance, inspection and warehousing. As a key transfer point in logistics management, efficiency of these terminals are critical to service quality. Each shipping container usually has an identification number and a corresponding freight vehicle number which can be tracked and recorded for verification of entry or exit from the terminal.

Inspection of vehicle license plates in complex lighting

Freight vehicle license plates and container numbers are usually not in fixed locations, and subject to inconsistent angles and lighting conditions. Identification numbers of containers are usually painted on their exteriors, in varying font color and clarity. License plate numbers are also not easy to detect in the ever-changing environment of container terminals.

AI Optical Character Recognition (OCR)

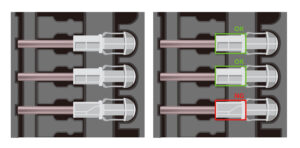

Solvison enables OCR for license plates and container numbers even when shapes, color and locations of characters vary, and are pictured in poor lighting conditions. The system builds an AI model using sample image training to automatically read and convert images into digitized information for inspection and logistics management tasks.

AI Inspection

Container number identification

License plate recognition