SolVisionCase Study

PCB Inspection Using AI

Case

PCB Assembly for Electronic Products

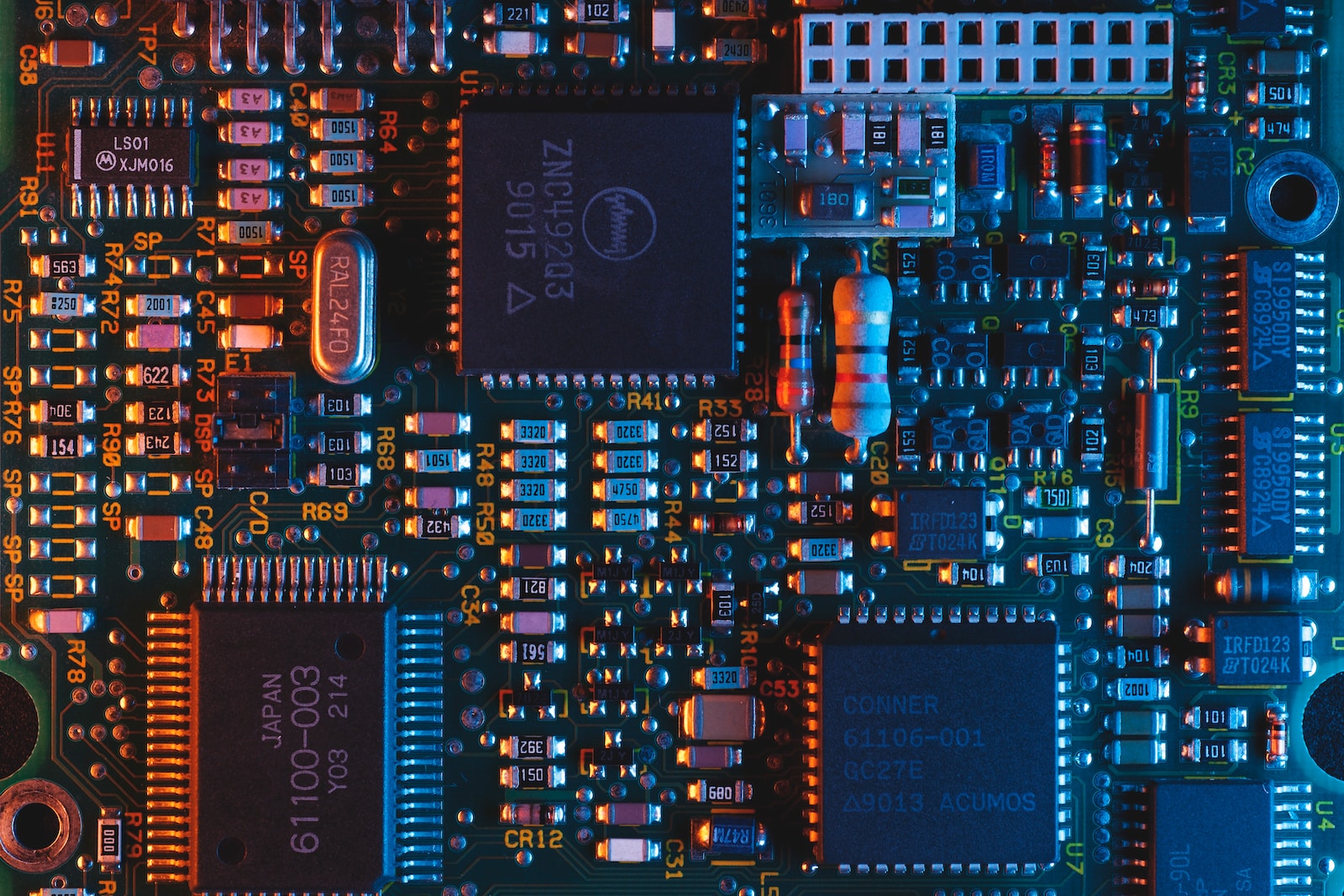

Printed circuit boards (PCBs) are the central backbone of electronic devices, serving as the platform for integrating various electronic elements. Following assembly, meticulous inspection becomes imperative to confirm the precise alignment and placement of components, matched with their designated serial numbers. This scrutiny is paramount to guarantee the functionality of the PCB.

Challenge

Inspecting Diverse PCB Components

Assembled PCBs contain a diverse array of electronic components, including resistors, capacitors, and transistors, each positioned according to the circuit’s layout and characteristics. These components exhibit variations in number, size, appearance, and assembly specifications, all essential for optimal PCB functionality. However, conventional rule-based inspection systems frequently encounter errors due to the complexity of PCBs, often requiring manual reinspection to improve detection accuracy. To meet rising production demands, there’s a pressing need for a more efficient inspection solution.

Solution

Enhancing PCB Inspection Efficiency with AI

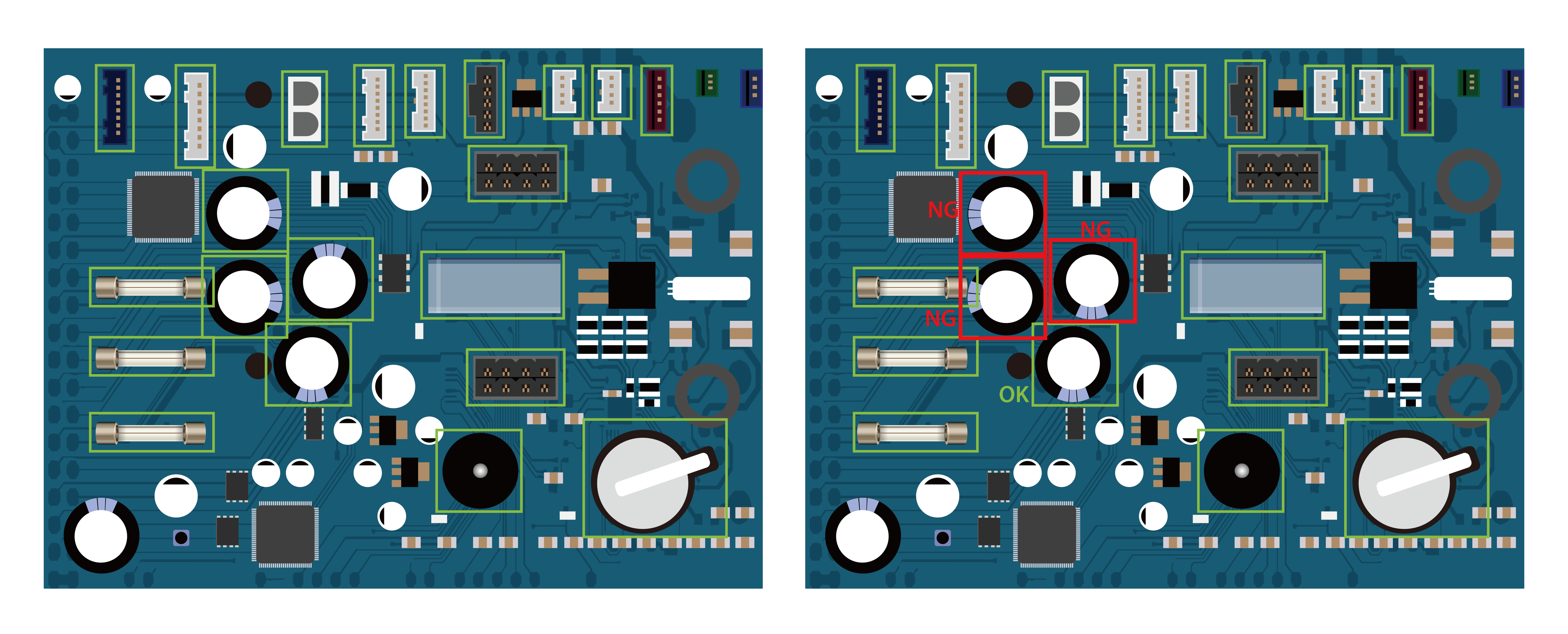

SolVision utilizes Solomon’s cutting-edge AI technology to optimize PCB inspection. It begins by meticulously defining the unique assembly characteristics of each component on the assembled PCB. The AI model learns to discern these characteristics using advanced image processing techniques, leveraging a golden sample as a benchmark. This approach facilitates the seamless identification of defective components, enabling real-time detection of anomalies like missing parts or assembly errors. As a result, production yield and quality are significantly enhanced, ensuring optimal performance of electronic devices.

Defect Detection

Golden Sample

Anomalies Detected