SolVisionCase Study

Visual Inspection of Stainless Steel Tubes

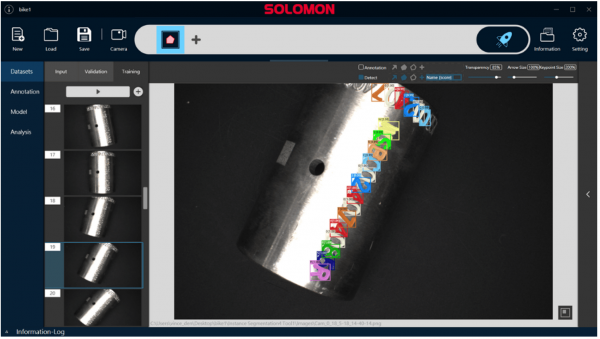

Optical Character Recognition (OCR) for Bicycles

Bicycle registration numbers

Bicycle thefts are common and are not easily recovered when lost. Printing identification information on bicycles can be a way to increase recovery rate. Manufacturers have started engraving unique numbers on bicycle frames before they leave the factory, and registering them in a database system for digitized tracking.

Stainless steel tubes and traditional inspections

Presently, labor-intensive manual inspection is still the method of choice for screening and registering bicycle identification numbers. Bicycle frames are often made of curved stainless steel tubes that easily refract light and make it hard to locate the engraved number. Manual and rule-based inspections leave lots of room for improving detection rates and efficiency.

AI powered Optical Character Recognition (OCR)

SolVision’s superior recognition capabilities ensures that OCR of bicycles can be accurately carried out regardless of how the identification numbers look or light refraction levels. The AI model can be easily trained using sample images to recognize characters on stainless steel surfaces.

AI Inspection

Highly reflective surfaces