META-aiviCase Study

Civil Infrastructure Monitoring and Inspection Using AR + AI

Customer

The customer is a municipal department in charge of water conservation and flood control projects in a city of 2.6 million inhabitants.

Case

Monitoring Pumping Station Water Supply

Ensuring homes and businesses have an adequate supply of water is a crucial function for local government authorities. To guarantee optimal flow distribution at water pumping stations it is vital to have an effective monitoring and alarm system that notifies operators immediately about any irregularities so that essential maintenance can be carried out without delay.

Challenge

Inefficient Monitoring Process and Delayed Response to Incidents

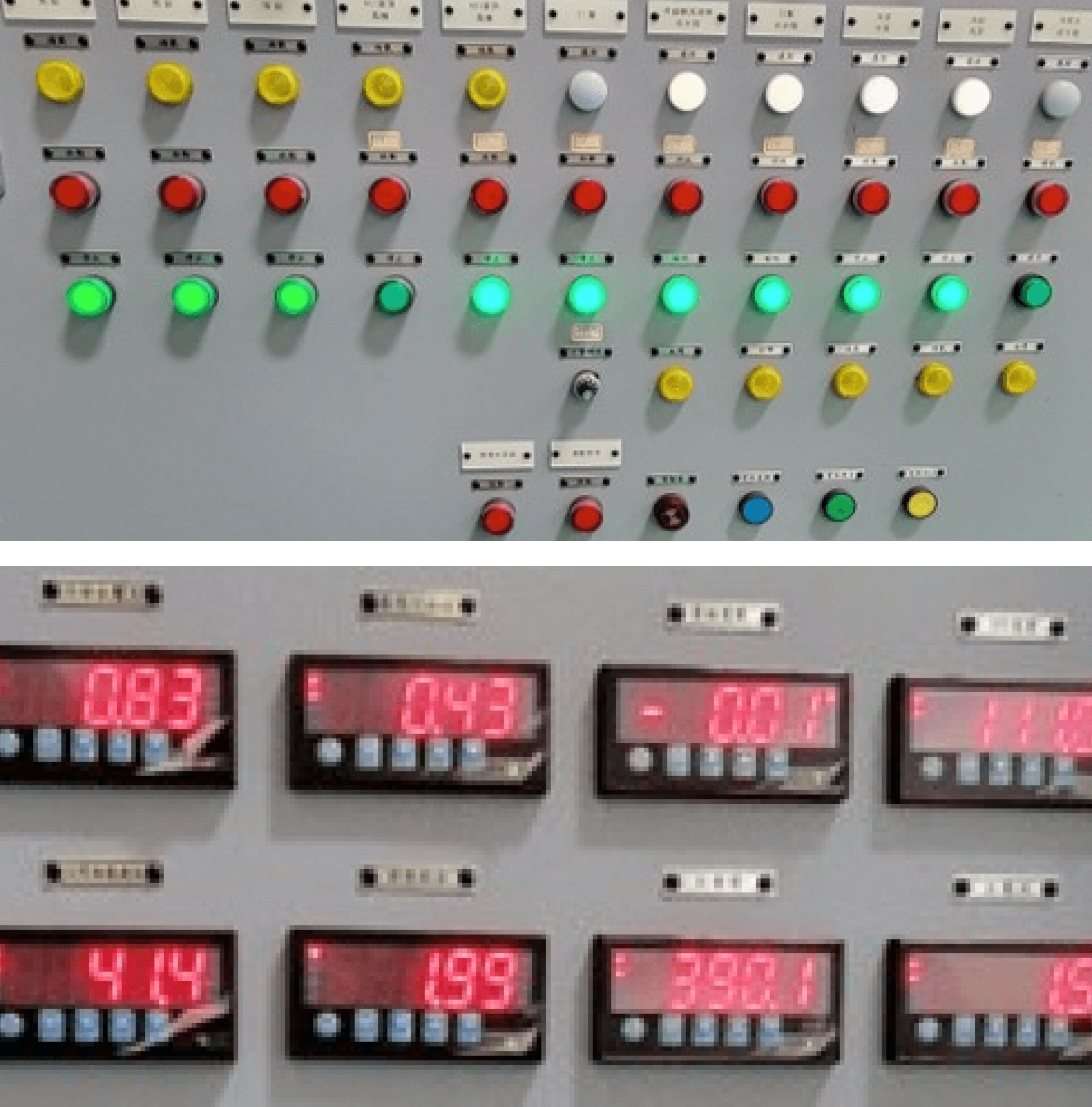

Water pumping stations rely on dozens of machines operating within specific parameters to ensure correct functioning at safe levels. At this site each machine is checked manually by an individual operator on a rotational shift basis – this was a laborious and time-consuming process, exacerbated by the size and complexity of the facility, which hindered the ability of operators to respond quickly to incidents.

Furthermore, the lack of an automated monitoring and verification process often resulted in mistakes or oversights due to human error, and without a systematic way to monitor (or record the process), whenever there was an incident it was difficult to trace the error and respond accordingly.

Solution

Detecting Malfunctions in Real Time with META-aivi

META-aivi uses AI models and OCR technology to constantly monitor gauge levels and panel indicator lights at the pumping station to ensure everything is operating correctly and within safe ranges. Our augmented reality solution integrates with the facility’s security and alarm system to instantly notify operators when there is a malfunction, so problems can be diagnosed and dealt with immediately. Also, META-aivi uploads the monitoring data to the customer’s server, creating a digital report for incident logging and future analysis.

META-aivi Inspection Results

1. AI models are built based on machinery values

2. META-aivi detects anomalies