SolVisionCase Study

Detecting Faulty and Missing Laptop Components

Optimizing laptop assembly processes with AI

Assembly and product quality

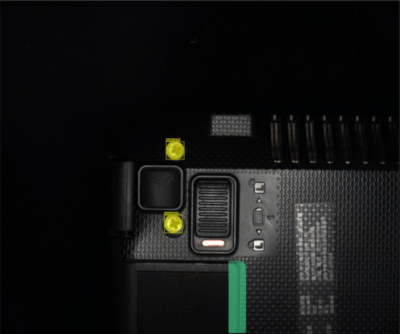

Laptop components in the assembly and packaging process are often matched and handled manually. As the top and bottom casings are assembled and the laptop is vertically screwed together, having missing parts will directly affect the final product quality. Malfunctioning products that reach sales channels are also more than capable of damaging the manufacturer’s reputation.

Human error in assembly processes

Occasionally, human error occurs during assembly of the final product, for instance loose screws or disconnected components. For repetitive manual tasks such as in this case, automated visual inspection can help identify defective products and improve workforce efficiency.

Improving yield and efficiency with SolVision

Powered by AI, SolVision first locates screws and electronic components using image analysis, then conducts preliminary recognition and classification of the different parts. The AI model is then trained to quickly identify the completeness of the assembly process. As the system validates more images over time, this allows continuous optimization of the detection process, effectively improving yield and quality of laptop assembly processes.

AI Inspection

Golden Sample

Misaligned Latch

Missing Component