META-aiviCase Study

Intelligent Remote Facility Management

Customer

The customer is a company in the semiconductor vertical that operates on a global scale.

Case

Key to Plant Management Efficiency: Intelligent Interpretation of Instrument Values

Effective inspection and maintenance play a crucial role in ensuring production efficiency and safety at semiconductor fabrication plants. To meet the increasing demand for electromechanical equipment management, incorporating instrument values into the maintenance management system has become an important process for the intelligent management of plant facilities. This ensures that factors such as adherence to inspection regulations, process efficiency, and reporting of abnormalities are closely monitored and managed.

Challenge

Lack of Automatic Identification System for Machine Data

Traditional machine data recording, which involves manual interpretation and paper documentation, is prone to errors and lacks standardization, resulting in low inspection compliance rates. In addition, traditional inspection methods lack automatic alarm systems for anomalies and provide inadequate data for managers to assess, making it difficult to detect hazards and causing machine malfunctions that decrease production efficiency. Implementing automated systems and standardizing inspection procedures can help improve compliance rates and increase efficiency in production management.

Solution

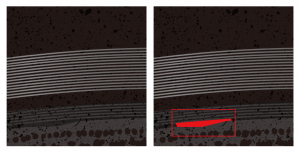

Smart Upgrade for Facility Inspection with META-aivi

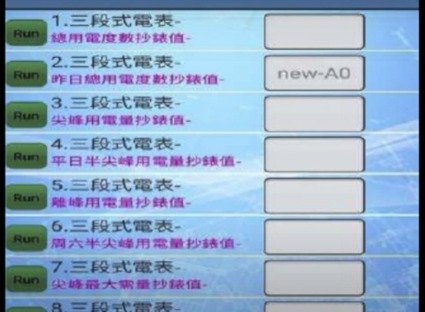

By implementing an intelligent facility inspection system using META-aivi, machine vision is utilized to perform Optical Character Recognition (OCR). The AI model is trained using various image samples of shapes and numbers, which is completed through the lens to detect data on the machine, automatically and instantly converting the AI-recognized value into digital information. This information is then sent to the cloud to create an inspection report, allowing plant operators to easily monitor facility inspection through mobile devices. In addition, safe ranges for machine values can be set—if the AI detects values outside of the safe range, the system will immediately issue an alert to notify personnel of the abnormality, allowing operators to respond promptly and resolve any issues.

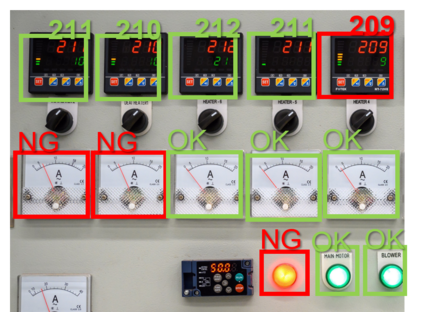

META-aivi Inspection Results

AI inspection of machine instrument readings using META-aivi’s OCR technology

Digital inspection records are generated for reporting and diligence