SolVisionCase Study

Automated Visual Inspection of Yarn

AI for maximizing production throughput and product quality

Demanding standards for yarn

Faced with intense competition and high labor costs, the Taiwanese textiles industry has shifted its focus to high quality low cost measures to differentiate and in consideration of production ROI. Maximizing throughput while maintaining product quality is currently the biggest challenge.

Limitations of conventional inspections

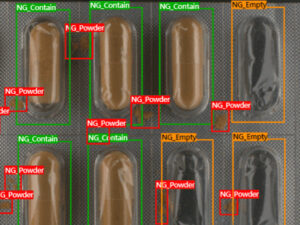

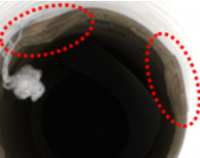

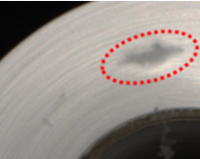

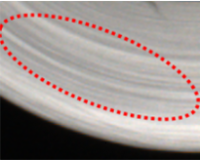

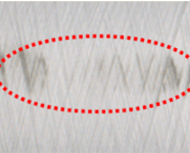

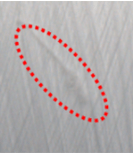

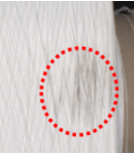

More often than not inspection of yarn is performed manually, which is a time-consuming and labor-intensive task. Missed inspections are also common as defects come in too many variations, from stains, deformation, knots, broken yarn, splitting, fuzzy edges to wrong color. When defects are irregular or come in large numbers, rule-based vision systems are prone to high rates of inaccurate detections and requires manual double checking. To improve labor productivity, yarn inspection needs a more reliable solution.

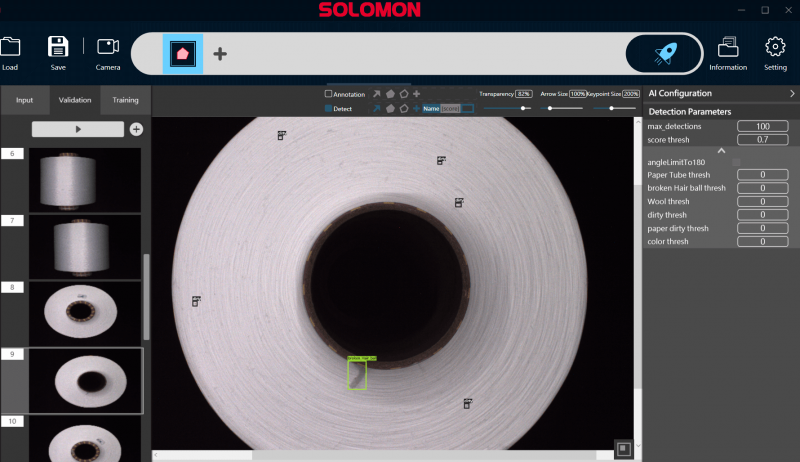

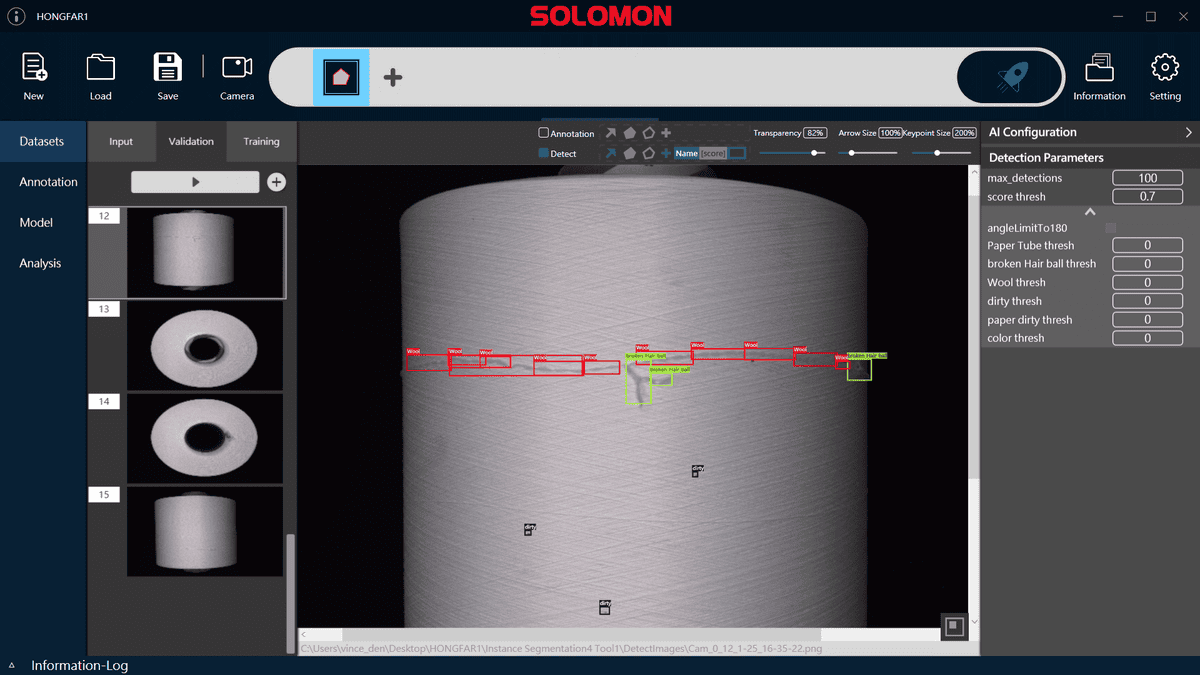

Detecting yarn defects with SolVision

Using AI powered SolVision, different types of yarn defects can be located and recognized by their features through image analysis. The AI model is capable of identifying flaws quickly and accurately to improve detection rates and production yield, while reducing the burden on manual inspection. As the quantity of available data increases, the system can continue to optimize the AI recognition process and allow training results to be quickly imported into various production lines.

AI Inspection

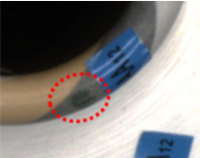

Paper tube stain

Broken paper tube

Broken yarn

Distortion

Dirty yarn

Needle marks

Broken yarn

Distortion