SolVisionCase Study

HDD Mounting Bracket Defect Detection Using AI

Case

Detecting Defects on HDD Mounting Brackets

The production of HDD mounting brackets is a critical and demanding task in computer assembly. These brackets play a crucial role in heat dissipation and operational efficiency, directly impacting overall computer performance. Ensuring their quality is essential for maintaining the reliability and longevity of computer systems.

Challenge

High Volume and Variation of Defects

HDD mounting brackets are prone to numerous defects during production, ranging from surface damage to incorrect shape or size. The vast variety and volume of these anomalies make precise identification challenging during manual inspection. Subtle defects, which are difficult to detect, can lead to assembly issues, such as misalignment with other components.

Solution

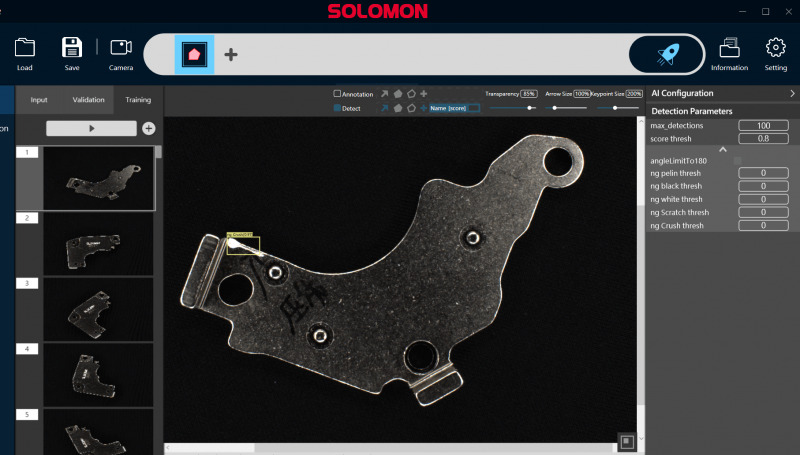

Enhanced Defect Detection with AI

SolVision’s segmentation tool leverages AI to improve the visual inspection of HDD mounting brackets. The system can quickly and accurately identify defects regardless of size, appearance, or variation by training an AI model to recognize various defect types based on shape. This advanced detection capability maximizes production throughput and ensures higher quality standards in electronics.