SolVisionCase Study

Packaging Seal Inspection Using AI

AI powered detection for quality control

Is the package really sealed?

Product packaging has a direct impact on product safety and quality. A proper seal preserves the contents of the package and ensures it is tamper-proof, making sure that no harm can come from consumption.

Minute differences in sealing defects

Determining whether a package is properly sealed requires examination of relevant production methods and the extent of underprocessing. Sealing defects do not have much variation but as the packaging material is often highly reflective, they are not easily detected by the human eye or traditional AOI inspection systems.

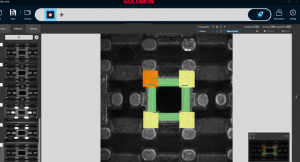

AI-powered sealing inspections

Based on deep learning technology, SolVision can determine whether a seal is intact by comparing a perfect packaging with potential variations – for instance incorrect sealing on the side, bottom, or all sides – to identify unsealed packages based on their features and help manufacturers understand where or how the error occurred during production.

AI Inspection

Golden Sample

Misplaced Label