SolVisionCase Study

Defect Inspection of Metal Casings Using AI

Case

Hardware Casing Quality Control

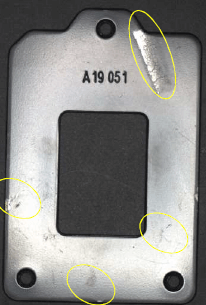

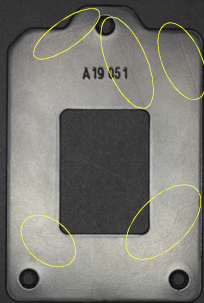

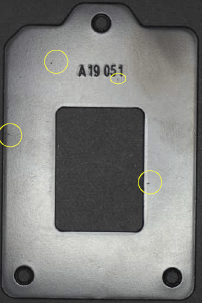

To ensure consistent quality, consumer electronic devices like PCs require the inspection of their hardware casings before assembly.

Challenge

Difficulties Inspecting Reflective Surfaces

Detecting subtle defects, such as scratches on metal surfaces, becomes challenging under normal lighting conditions, as they are barely visible to the human eye. This makes manual inspection tasks difficult to perform.

Solution

Efficient Inspection and Classification with SolVision

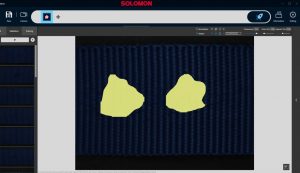

With SolVision‘s segmentation tool, the AI vision system can be trained to identify various defects based on their distinctive features. It then builds a database categorizing defects into customizable groups, such as ‘Obvious Defects’, ‘Minor Defects’, and ‘Micro Defects’. Through AI deep learning, the system recognizes defects, enhancing inspection accuracy and speed by disregarding smaller, acceptable defects. This ensures that unsatisfactory products are prevented from entering the assembly process.

Classification

Obvious Defects

Minor Defects

Micro Defects