SolVisionCase Study

AI Inspection of Rubber Tires

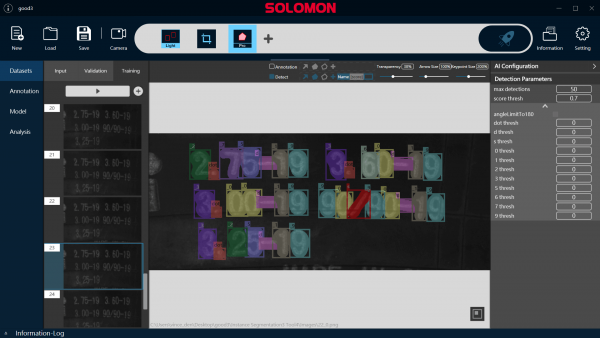

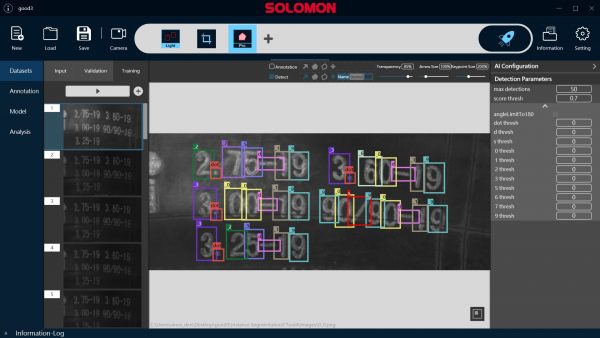

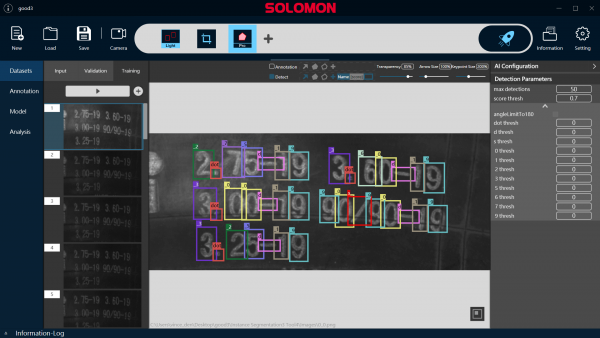

Recognizing printed characters with SolVision

Serial numbers on inner wheels

Inner wheels are rubber rings that each have a corresponding serial number to help identify its model specifications and matching tire size. To prevent inflated inner wheels from wrinkling and to reduce pressure of the outer tire, in order to extend the tire’s service life, recognizing the serial number to match it correctly with a suitable outer tire is a crucial step in production.

Serial numbers are tricky

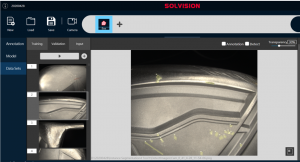

Tires undergo numerous high pressure, high load, and high temperature processes during manufacturing. Dust generated by machinery, equipment, or airborne in the environment, plus the extended operation time of printing can all cause the serial number to become blurry or have uneven colors. Defective serial numbers are hard to manually screen, and even with the aid of traditional rule-based systems, the recognition process remains inefficient.

SolVision: the answer to visual inspection

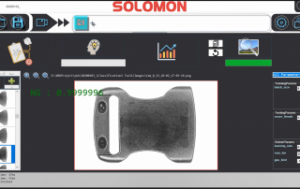

With SolVision, sample images of defective serial numbers can be used to train an AI model to perform Optical Character Recognition (OCR) for accurate analysis of different text and numbers. Even with ambiguous printing or uneven colors, SolVision can quickly identify and read serial numbers to ensure better visual inspection processes.

AI Inspection

Clear Text

Blurry Text