META-aiviCase Study

PCB Inspection Using AR Glasses

Customer

The customer is a Fortune Global 500 company providing solutions to telecommunication companies and cloud service providers worldwide.

Case

Electronic Component Inspection

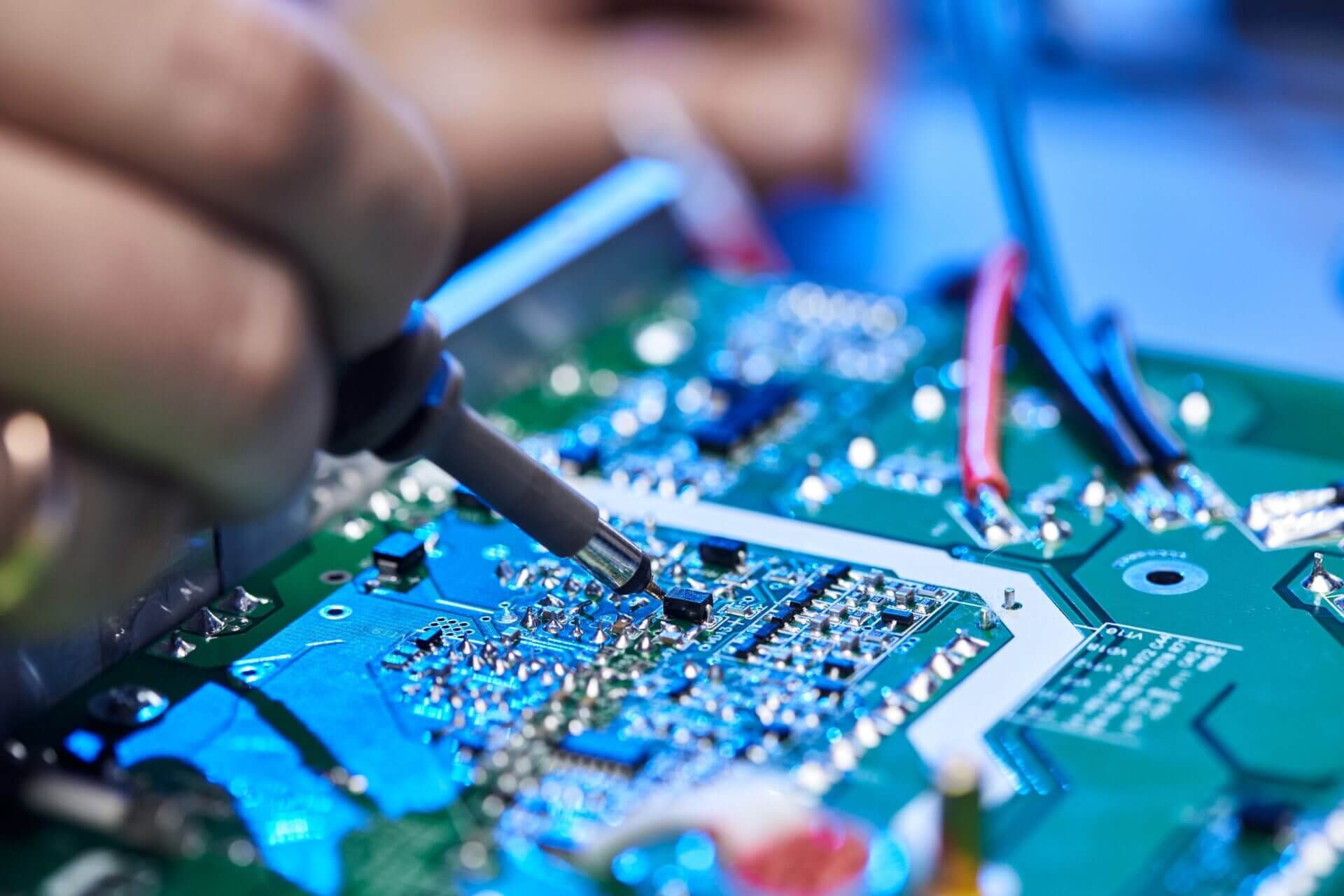

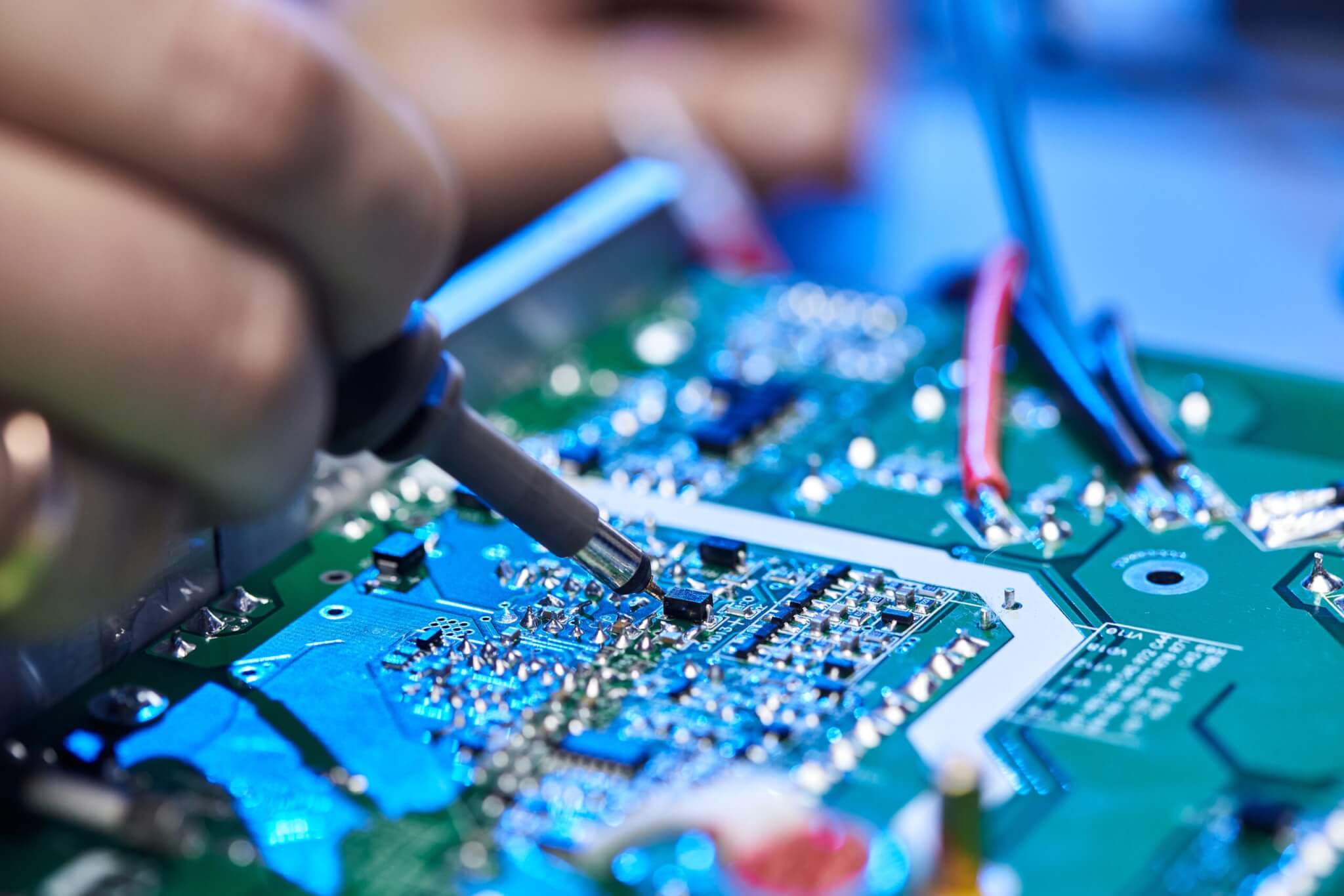

PCB inspection is a complex multistep process. Verifying correct assembly requires identification and placement of all the right components in their corresponding sockets.

Challenge

The Cost of Human Error in Electronics Manufacturing

PCB assembly is traditionally carried out manually; however, the reflective nature of PCB components increases the likelihood of human error due to fatigue and eye strain from prolonged exposure to reflected artificial light. Errors during the assembly process – such as missing or incorrectly placed components – affect PCB functionality and impact overall product quality. To negate this the customer wanted a reliable inspection solution that could intercept errors made during assembly.

Solution

Optimizing Inspection with META-aivi and RealWear Glasses

Using AR glasses with META-aivi, operators are able to accurately identify PCB components and verify that they have been placed correctly. Operators are also able to immediately detect any assembly errors and rectify them. The inspection results are uploaded simultaneously to the customer’s server – enabling the customer to analyze the inspection data and make improvements to their assembly and quality control procedures.

META-aivi Inspection Results

META-aivi detects assembly anomalies